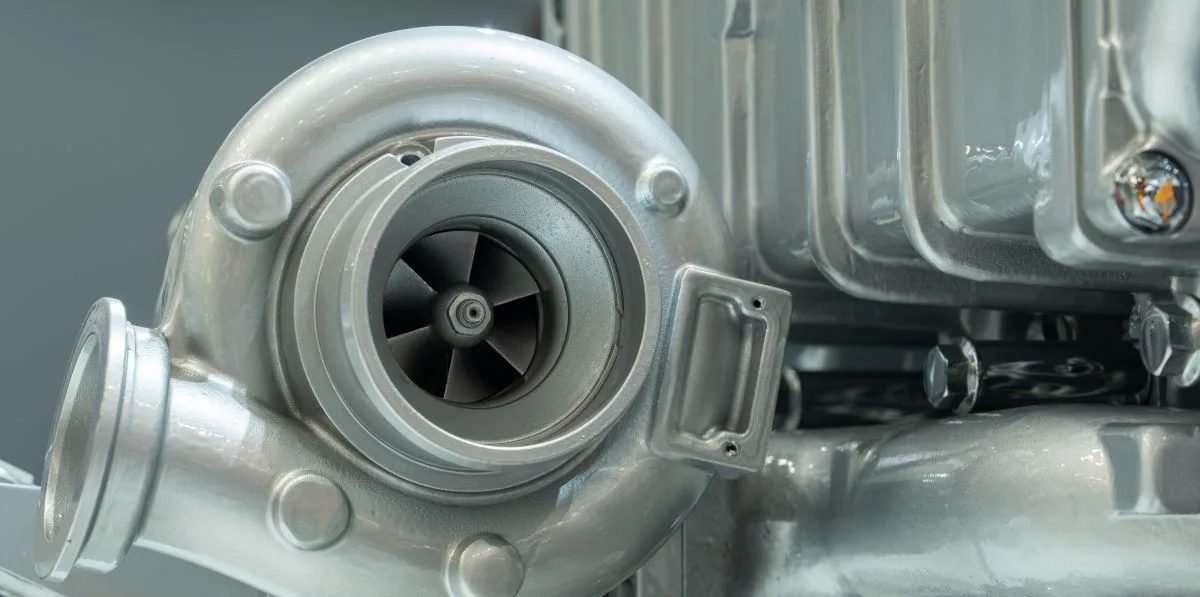

The Customer: A Long-Standing Automotive Supplier

CZ a.s. is a multi-branch company with more than 80 years’ experience in engineering production. Located in the Czech Republic, most of their manufacturing is for the automobile industry. One of the products they are making is high quality turbochargers for commercial diesel applications.

Having started their turbocharger production in the early 1980s, CZ a.s. has been expanding their production as well as their research and development efforts each year. Their range of turbochargers include approximately ten turbocharger families suitable for engines with a displacement from 1 liter up to 16 liters. CZ a.s. is offering the complete package of turbocharger development, validation, and serial production for the customer to have it just in time.