How It All Started

It all began with guidance on fastening technology. For three years, we cultivated a relationship with Valley Enterprises, a company of Gemini Group, through consistent communication and exploratory projects.

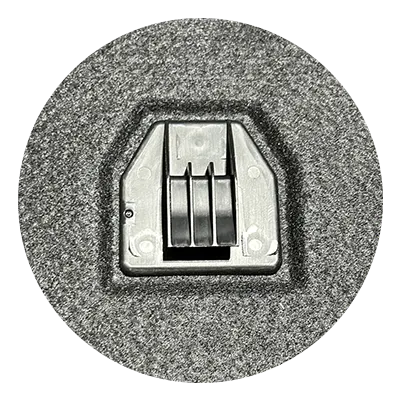

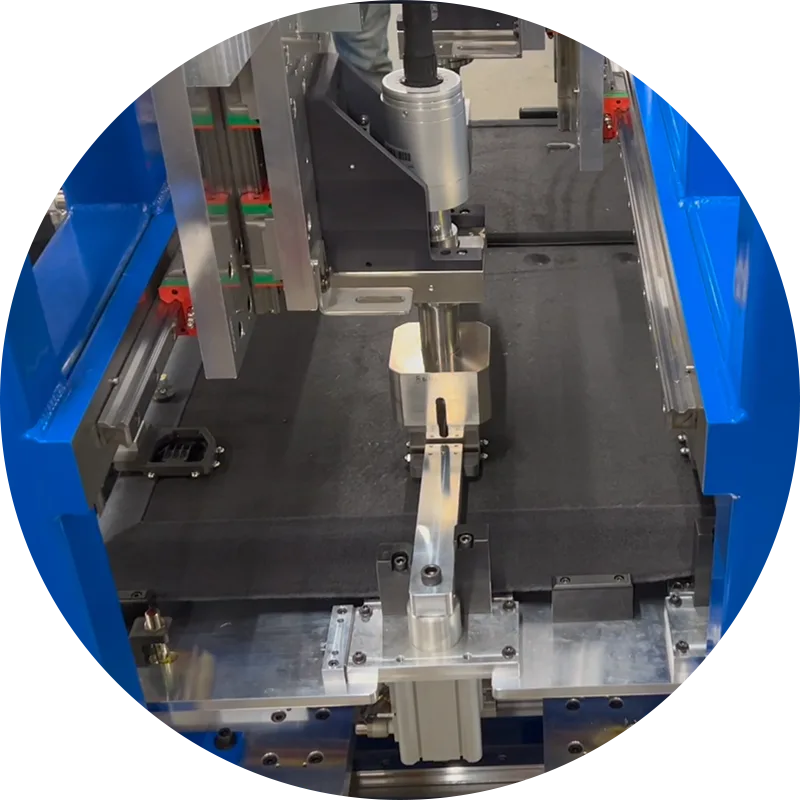

We successfully demonstrated the capabilities of our MultiMaterial-Welding® (MMW) technology in a load floor project for the Jeep Wrangler, which paved the way for a subsequent project with Stellantis’ Daytona/Charger. With the OEM already familiar with and confident in our solution, the project received swift approval.