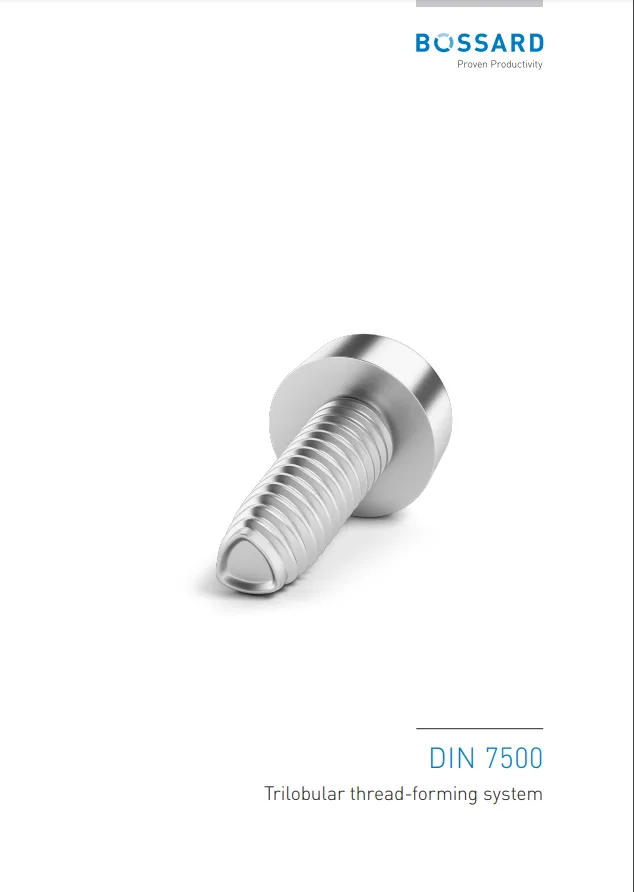

DIN 7500 Benefits

Benefits

Performance

Increase the joint strength and vibration resistance of your application.

Benefits

Optimize your fastening connection with a premium multifunctional screw.

Benefits

20-30% Cost Savings

compared to conventional fastening technology

Benefits

By eliminating work steps and reducing your C-parts inventory, the DIN 7500 screw unlocks new cost saving potentials.

Benefits

No More Tapping

Tapping the mating thread in the component is no longer necessary.

Benefits

DIN 7500 thread-forming screws create their own thread in malleable materials – no extra work steps necessary.

Benefits

Metric Thread

The DIN 7500 creates an ISO metric thread.

Benefits

If a thread-forming screw is lost, it can easily be replaced with a standard screw.