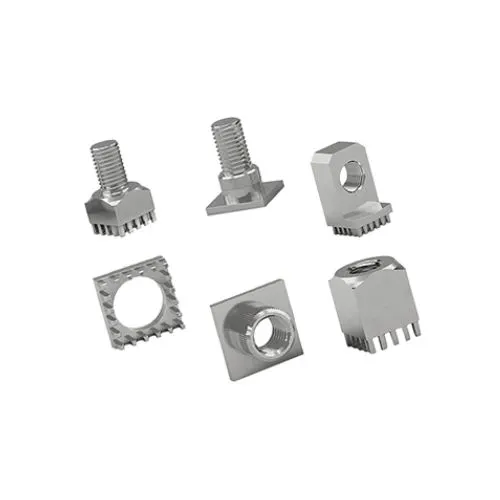

MTCON Power Elements

Power elements provide reliable solutions for supplying printed circuit boards (PCBs) with large electrical power and currents. They enable wire-to-board connection between a wire and a PCB, as well as connections between circuits. Components such as screwed fuses, relays, or busbars can also be connected to the power elements.

The MTCON portfolio includes a large array of power elements for various requirements. Examples include:

- Power Towers and Power Sockets that attach cable lugs, midi or mega fuses, and other items to PCBs.

- Power Edges allow connections of high-current relays, cable lugs, and more.

- Power 2 Ground allows fastening cable lugs or large, heavy components such as battery disconnectors to PCBs. In addition, it protects the circuit board from mechanical stresses.

- Power Protectors act as protection against contact and twisting, while preventing short circuits in nearby components.