Controller and Energy Source

The controller is the heart of the SWS system. It controls the welding energy and stud movement. It also enables process monitoring, including documentation in real time. The energy source can be assigned five welding outputs, thus guaranteeing high efficiency and economy.

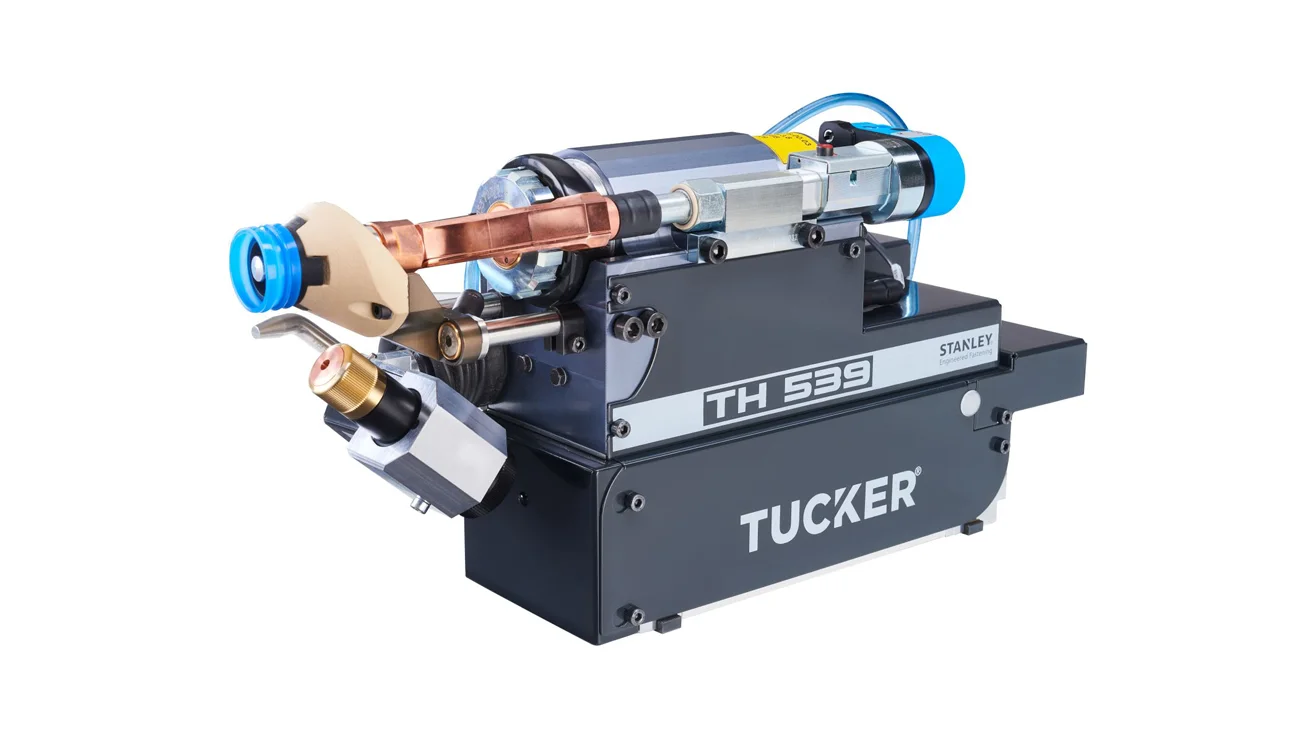

Feeder

The feeder units ensure low impact separation of the welding studs and reliable feeding. The feeding process can therefore be fully monitored and event-controlled.

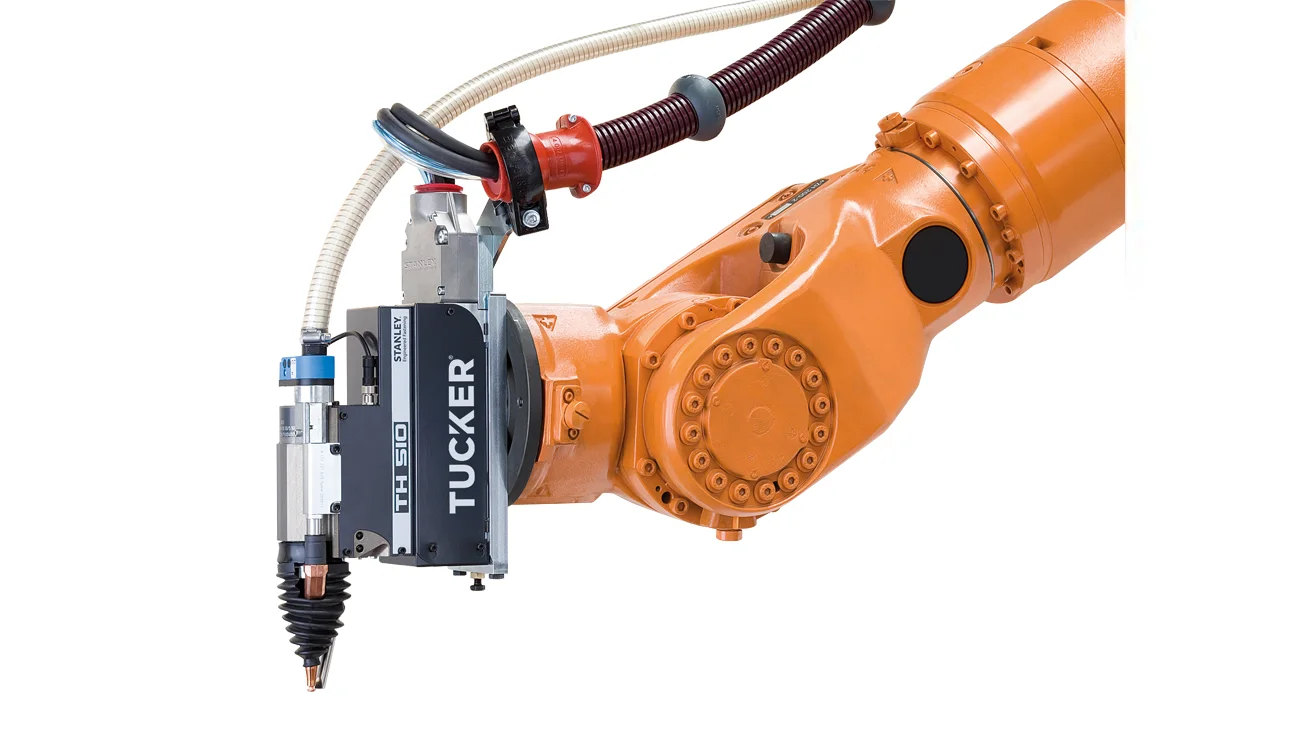

Welding Head

The welding head is suitable for steel applications, gas-assisted welding for aluminum and CrNi materials, and high-strength steels. Low-spatter welding is possible. Depending on the requirements, different options can be individually selected for the applications.

Stud Welding Gun

Manual welding guns are available for semi-automatic and manual applications. All Tucker® guns use a linear motor and have an integrated right-angle sensor, which contributes to the quality of the weld.

Tucker stud welding guns enable both steel and gas-assisted welding of materials such as aluminum or CrNi materials and high-strength steels.

Additional Equipment Options

We offer additional technologies and options to improve your production processes and meet complex requirements. Numerous extensions to the Tucker SWS system are available, including:

- The CleanJet surface cleaning system, for example, in aluminum applications

- TSD stud diverters to reduce the number of welding tools

- The TCS cleaning station increases the service life of welding tools

- Hose packages and cable routing systems reduce maintenance intervals

- Stud testing tools