Why You Should Procure Your Special Parts and Custom Fasteners from Bossard

Fewer Suppliers

Reduce the number of suppliers you are working with and cut unnecessary overhead.

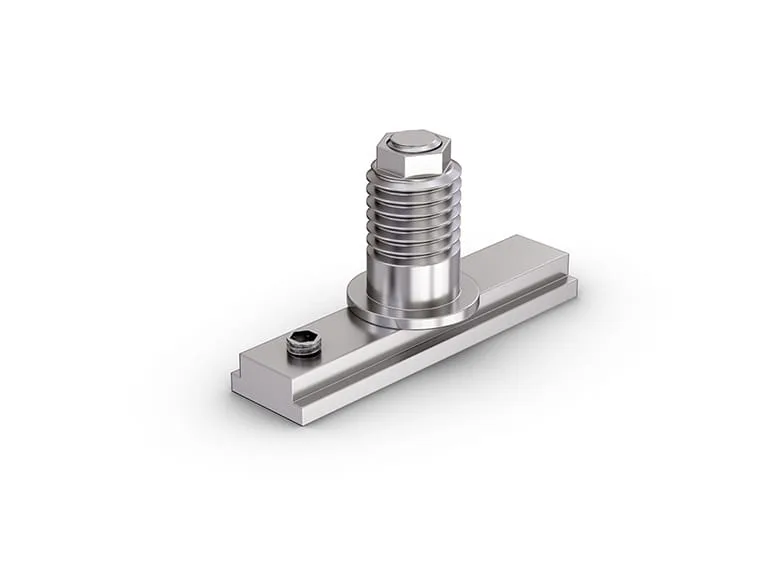

Comprehensive Engineering Services

Benefit from our engineers’ expertise in all things fastening.

Consistent Quality

We only work with selected suppliers that fulfil rigorous standards to ensure top product quality.

Smart B- and C-Parts Management

Optimize your supply chain further with our smart factory logistics services.

Flexible Release Quantity

Whether you need bigger quantities or just a few parts for your prototype, we’ve got you covered.

More Free Capital

Reduce your inventory, become leaner, and free up capital to invest where it matters.