Expert Design

Want to explore innovative approaches that offer a better time-to-market? Design engineers often rely on traditional fastener selection methods. This case study highlights the potential of exploring different technologies.

The company 5M develops and manufactures components for various applications in the transportation industry. For railways, they produce flat and 3D-shaped panels from a lightweight yet high-strength composite material, primarily used for interior linings such as floor panels, side walls, and ceilings.

In general, different fastening technologies could be used to create fastening joints for assembly in this application of laminated polyurethane (PUR).

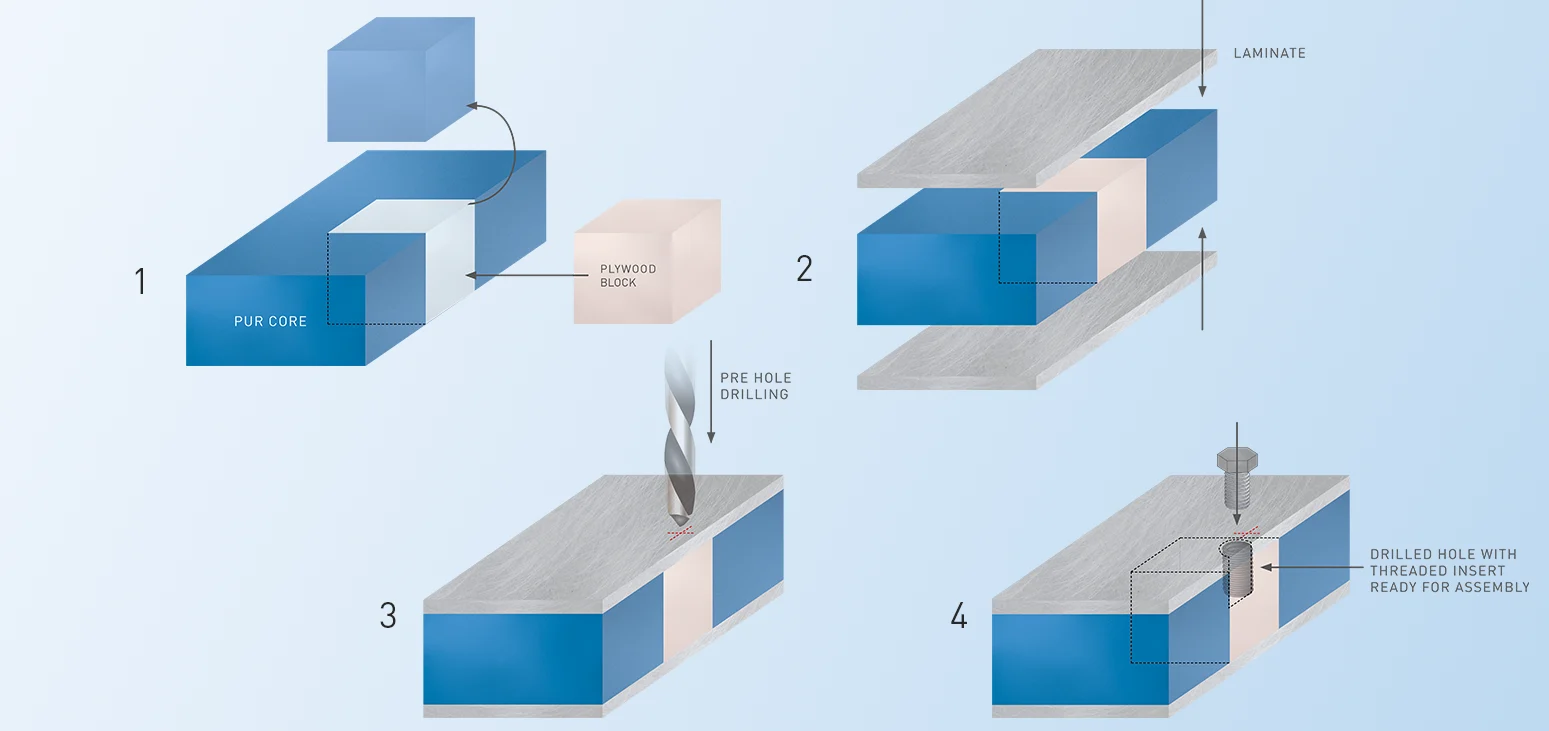

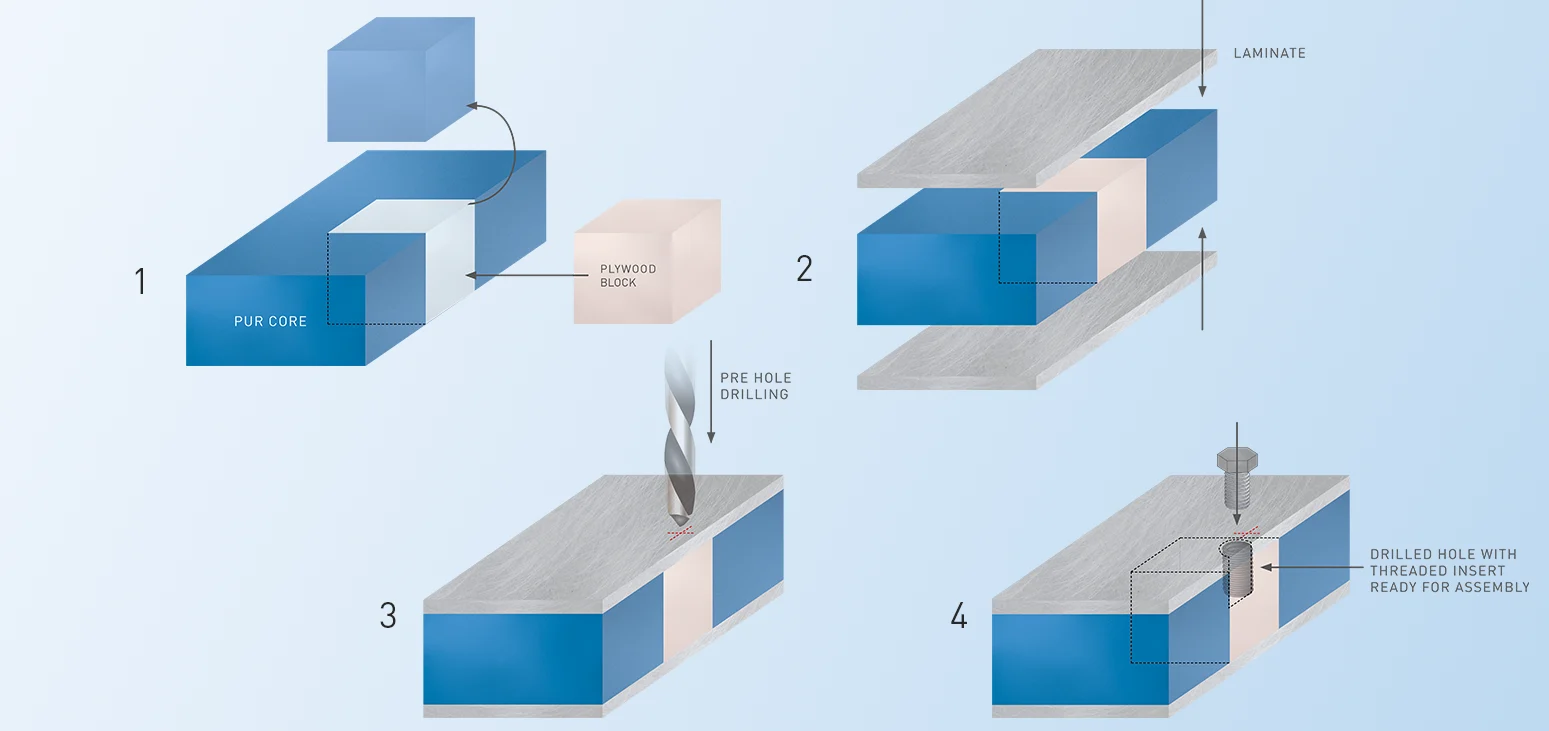

5M sought new methods for creating fastening points in their sandwich materials. The existing approach included traditional fasteners. They used adhesives to add a plywood block to accommodate threaded inserts. Compared to the new solution, this was time-consuming, expensive, and prone to errors. Today, they use a LiteWWeight® Double Pin, applied through MultiMaterial-Welding technology into the sandwich panel.

MultiMaterial-Welding®: How the technology helped 5M s.r.o. to streamline manufacturing